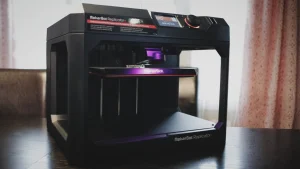

The manufacturing industry has been revolutionized by 3D printing. It has enabled manufacturing industries to be extremely precise and refine the details in an unprecedented manner. 3D printing technology is currently used for all products, from everyday household items to building complete buildings.

The success of 3D printing technology makes one wonder how does a 3D printer work, and it is precisely what we will discuss in this article.

Let’s get to it.

Understanding 3D Printing Technology

In simple terms, 3D printing manufactures three-dimensional objects from a digital file. The digital file is created on various programs based on the type of industry and then used to create a three-dimensional item layer by layer. It gives the designer complete control over all design aspects, enabling them to develop a product with a perfect finish. 3D printers can also design an item from pre-fabricated files, meaning you would not have to invest in software and designers.

Since most of the work is carried out by printers, 3D printing reduces manufacturing costs by cutting labor expenses. Furthermore, it helps create objects that are otherwise impossible with traditional manufacturing.

The primary shortcoming of 3D printing is that it is still developing; a lot can be improved. Furthermore, 3D printers can take a lot of time to design an item, which renders them inappropriate for some industries.

Right now, 3D printing technology is employed in several industries, including aerospace, medical devices, mechanical engineering, automotive, and tool-making. Some construction companies have also utilized 3D printers to erect several projects. Overall, 3D printing is a booming industry; Acumen Research and Consulting forecast predicted it will reach 41 billion by 2026.

Additive Manufacturing Process

3D printing is also known as the additive manufacturing process, which means creating an object by adding different layers of material together. It is opposite to traditional manufacturing, also known as subtractive manufacturing. The conventional method involves removing material a block of material to create an item. Cutting wood to manufacture furniture is an example of such manufacturing.

While the fundamental of additive manufacturing processes remains the same, it has different types, which differ based on how the layers are joined together. Stereolithography, Digital Light Processing, Fused Deposition, Selective Laser Sintering, and Selective Laser Melting are a few types of additive manufacturing. It is essential to understand the mechanism of each technology and the benefit it offers before using it for any type of manufacturing.

Understanding The Software For 3D Printing

Software plays a critical role in 3D printing. As discussed earlier, 3D printers create an object from a digital file created by the software. In addition to designing a digital file, several other applications are used in 3D manufacturing. Let’s take a look at them;

CAD Modeling

Computer-Aided Design or CAD software is a broad term for applications employed in different industries to design prototypes and finished products digitally. There are several types of CAD Modeling applications, each serving a specific purpose. Some of them suit better to construction industries while others will perform better for automotive designs.

The popular CAD Modeling apps used for 3D printing include AutoCAD, CATIA, OnShape, LibreCAD, TurboCAD, and FreeCAD. Understanding what these applications are designed for before incorporating them into the 3D printing process is essential.

Slicing Software

Unlike traditional printers that can interpret traditional digital files, including docs, pdf, jpeg, etc., 3D printers can only understand the file in G-code. Thus, the files you have created via CAD modeling applications must be translated into G-code so the printer can design the object. The applications that convert digital files into G-code are known as Slicing Software.

Some popular slicing applications include KISSlicer, IdeaMaker, Octoprint, Cura, Slicer 4.0, PreForm, SuperSlicer, Craftware, and Slic3r. You can get a free trial of some of these applications, while others need subscriptions immediately.

Understanding the Components of a 3D Printer

While looking for a 3D printer on the market, you will come across several terms describing different components of the printer. It is essential to understand those terms to make the right decision regarding a particular printer.

1. Thermoplastic Filament

Thermoplastic Filament is the raw material for 3D printing. It covers a range of materials that become moldable when subjected to heat and solidify when cooled. Furthermore, it is the most widely used material for 3D printing, primarily because of its low price and lack of adhesives. Popular thermoplastic filaments include high-impact polystyrene (HIPS), polyvinyl alcohol (PVA), polyethylene terephthalate (PET), and Nylon.

Thermoplastic filaments can also be classified based on their applications, including standard plastic, flexible, and exotic filaments. Before employing them in your printer, you should research these materials extensively and understand their pros and cons.

2. Extruder Mechanism

3D printers use thermoplastic filaments to heat them and convert them into semi-solid shapes to create successive layers of different objects. The part of the printer that ejects semi-solid and viscous material is called an extruder. In some printers, the extruder has only one function: solidifying bonding agent fed in powdered form. Extruders can be categorized further based on how they pass the material onto the plate.

Bowden extruder passes and pushes through a long but flexible tube called PTFE or Teflon tube to the heating element. Another type of extruder, a direct drive, is closer to the heating end and does not use a long tube. The type of extruder influences the kind of thermoplastic filaments compatible with the 3D printer.

3. Build Plate

The build plate is one of the most critical components of a 3D printer. The printer cannot pour out the semi-solid or liquid filament anywhere. Furthermore, the first layer has to be held in place so it does not move sideways while other layers are being printed. It is ensured by building a plate, which forms a bond with the first layer and holds the object in place.

The market offers several types of build plates, but they can be divided into two broad categories. One type uses the same material across the surfaces and does not need additional stickers, while others require special coating where the first layer rests. Each of these plates works better with one filament than the other. You should look the one that is compatible with your printer.

4. Heating Elements

The heating element is typically located within the extruder, and as the name suggests, it heats the filaments and turns them into a liquid or semi-solid state. Within the extruder, a cooling element prevents the heat from reaching the component where it is not needed. Another essential part of the heating mechanism is the thermistor, which regulates the temperature and prevents over or under-heating.

Once the heating element melts the filament, it is transferred to the build plate via a nozzle to create layers of the object.

How To Get the Best Results With a 3D Printer

While 3D printers have made manufacturing extremely simple, there are some points that must be taken into account to get the best results. These include the following;

Level The Build Plate

The build plate must be leveled appropriately and have the nozzle at an optimal distance, known as Z-offset. You can ensure it by incorporating sensors such as BLTouch. These will also automate the entire process.

Optimize Temperature

The temperature of the nozzle should be optimal – neither too low nor too hot. There are ways to control the temperature of different types of items. For example, adding a centimeter cube on the opposite side of the build plate during slicing will allow the printed layer to cool down before the next one is printed onto it.

Maintenance of Printer

Regular maintenance goes a long way to improve the final quality of the 3D prints. In addition to upgrading mods, you should invest in accessories to clean and lubricate different components. It smoothens the operations and helps create more refined objects.

Protect Filaments From Moisture

Most filaments in 3D printers are hygroscopic, meaning they will absorb moisture from the air. Exposing such filaments to air will damage them, and you will not get the desired quality. Such filaments include nylon, ABS, and other flexible materials. You should protect them from moisture by using a special storage compartment.

Invest in Post-Processing Techniques

Post-processing techniques can differentiate between a fine product and a premium product. It is the most overlooked aspect of 3D printing, but investing in it can lead to exceptional results. While most post-processing can be done manually, it is not sustainable for larger projects. There are technologies to automate the entire process, which is where you should invest if you want to scale the business.

Generally, post-processing can be classified into five broader categories: fixing, cleaning, coloring, surface finishing, and hardening. Some can be done with simple accessories, while others require complex machines.

Conclusion

3D printers are the talk of the town in manufacturing industries, but the terminologies used in this industry can be overwhelming for beginners. It is essential to understand how a 3D printer works and what role different components play during the process.

You must realize the different types of filaments used in manufacturing, compatibility with extruders, and the factors needed to optimize the process to choose between the different types of 3D printers.

We hope this article has been helpful!